- BODY fabric and zipper TAB fabrics

- Zipper with 1.25" (32 mm) tape width such as a YKK #5 coil zipper

- One Zipper slider

- HeatnBond Ultrahold adhesive sheet with paper backing

- Iron and pressing surface

- Sturdy brayer, pressing roller or wooden spoon

- Clips and/or pins

- Scissors or rotary cutter

Materials

Bonded Zipper Pouch

This project leans into bonded seams but can easily be mixed with sewn seams where you prefer. The pouch has a folded bottom for volume so it can stand up, plus an optional attachment point at the zipper end for an accessory loop.

Before You Start

Bonding results vary a lot by fabric. Coatings, face finishes, and fiber content all matter. Take a few minutes to practice on scraps.

Apply HeatnBond Ultrahold to the wrong side of fabric first. Follow the packaging instructions as a baseline and then experiment with heat level. You first press with the paper backing on. The adhesive should soften and grab but not flow freely away from the fabric.

Avoid getting adhesive on the iron. If it happens, it can be cleaned with a specialty iron cleaning product such as Faultless Iron Cleaner

Once the adhesive is fused to one fabric layer, remove the paper backing and adhere the second fabric layer with wrong sides together. While still hot, roll firmly and then allow the bond to cool fully before handling. Finish with a simple peel test. If it peels easily, increase heat slightly or slow down your pressing.

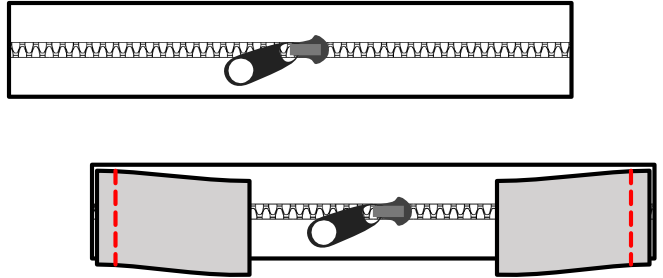

Step 1. Prep the zipper

For ease and strength, sew fabric tabs onto the zipper ends to create a non separating zipper from coil tape. The tabs are used here because of the scant 1/4" (6 mm) seam allowance, which helps maximize the zipper opening.

If you are cutting from a continuous roll of zipper tape, use the ZIPPER GUIDE pattern to cut the zipper to the correct length.

Attach the zipper slide.

Place one TAB right sides together with the zipper tape. Sew using a 1/4" (6 mm) seam allowance. Repeat on the other end and triple check the zipper slider is installed.

Step 2. Add adhesive to the zipper tape

Turn the TAB outward to open the seam first. Then, on the right side of the zipper tape, press a 3/8" (10 mm) strip of Ultrahold along the full top edge of the tape, from one TAB across the zipper to the opposite TAB, leaving the paper backing in place. This ensures the adhesive bonds evenly along the zipper and tabs.

While still hot, roll firmly with a brayer, or press by rubbing with a wooden spoon, to secure the adhesive. Pay particular attention at the intersection of the zipper tape and the fabric TAB. Repeat with another strip along the bottom edge of the zipper tape.

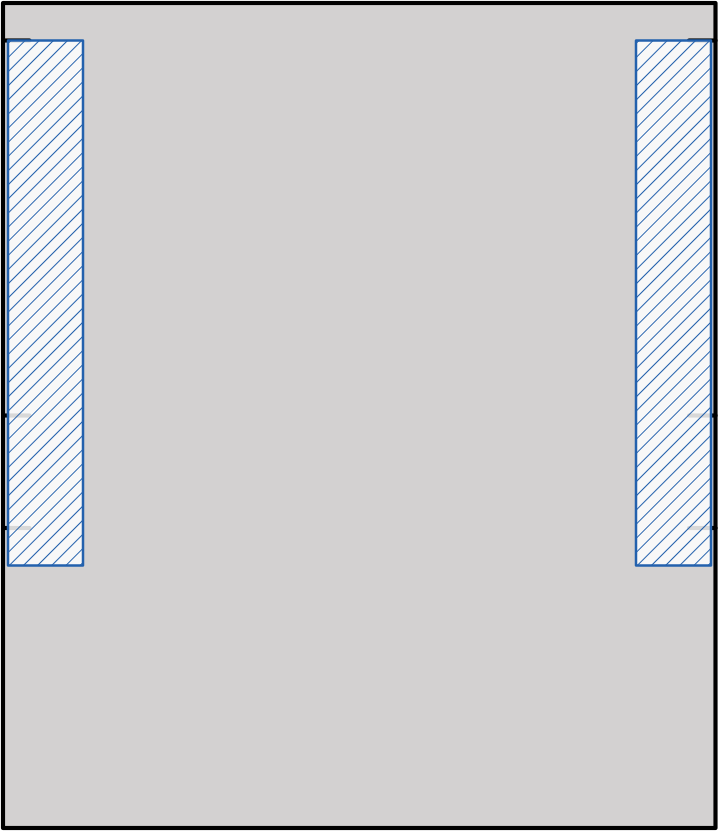

Step 3. Prepare the BODY panel

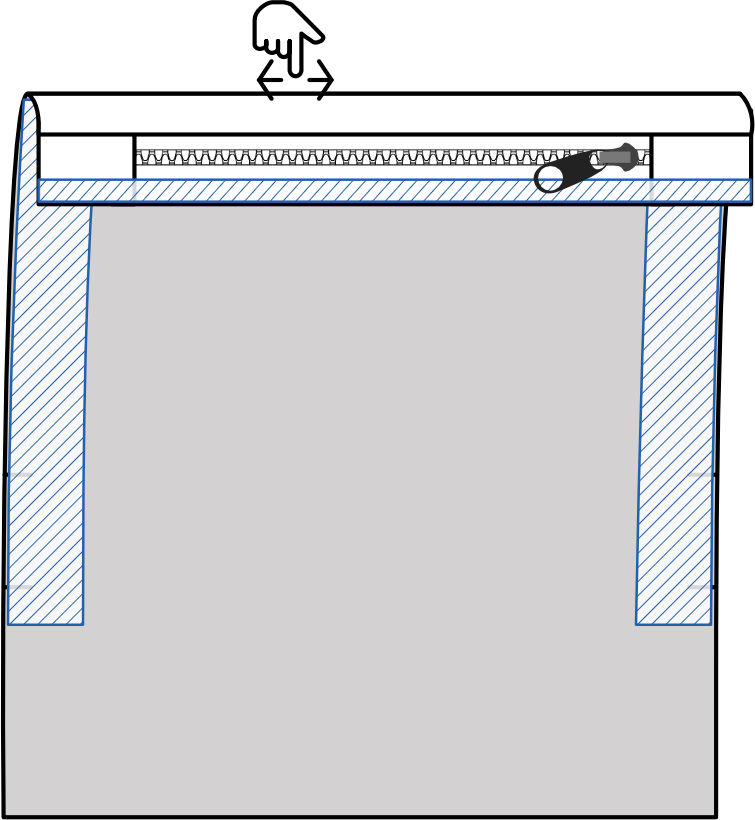

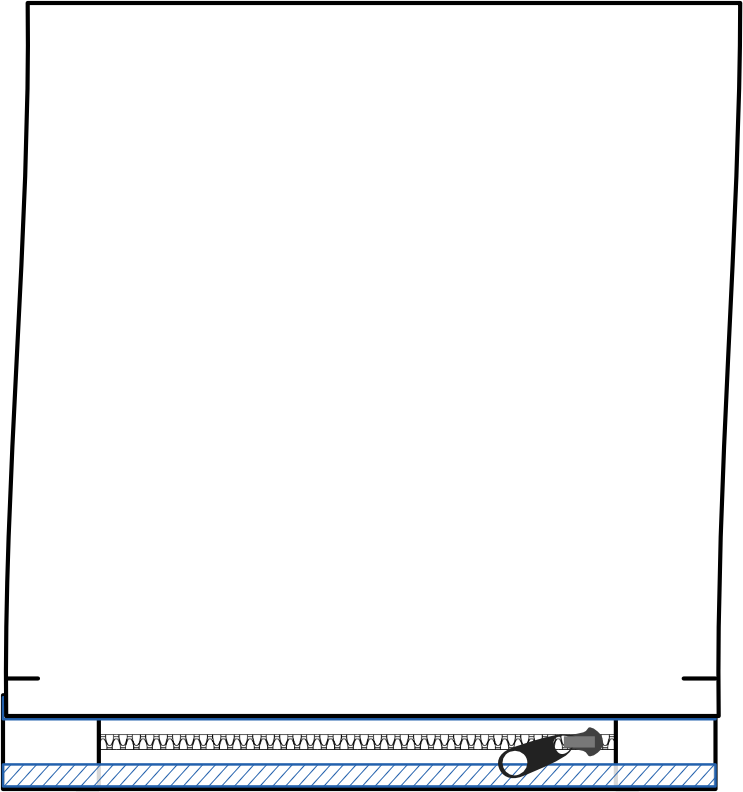

Step 4. Bond the top edge to the zipper

Orient the zipper slider for your preferred closing direction.

Remove the top paper backing from the zipper tape itself. Find the two notches 1/2" (12mm) from the top edge of BODY. Align the wrong side of the BODY panel to the right side of the zipper tape, fully covering the 3/8" (10 mm) adhesive. The raw edge of BODY should touch the edge of the adhesive near the zipper teeth.

Heat and press, then roll firmly to secure.

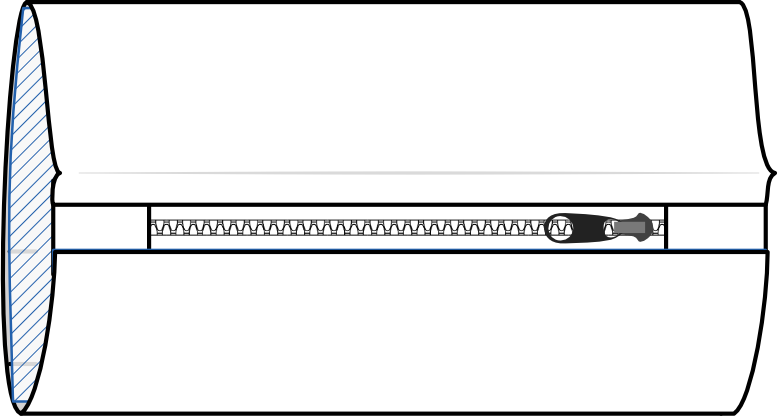

Step 5. Crease the top edge

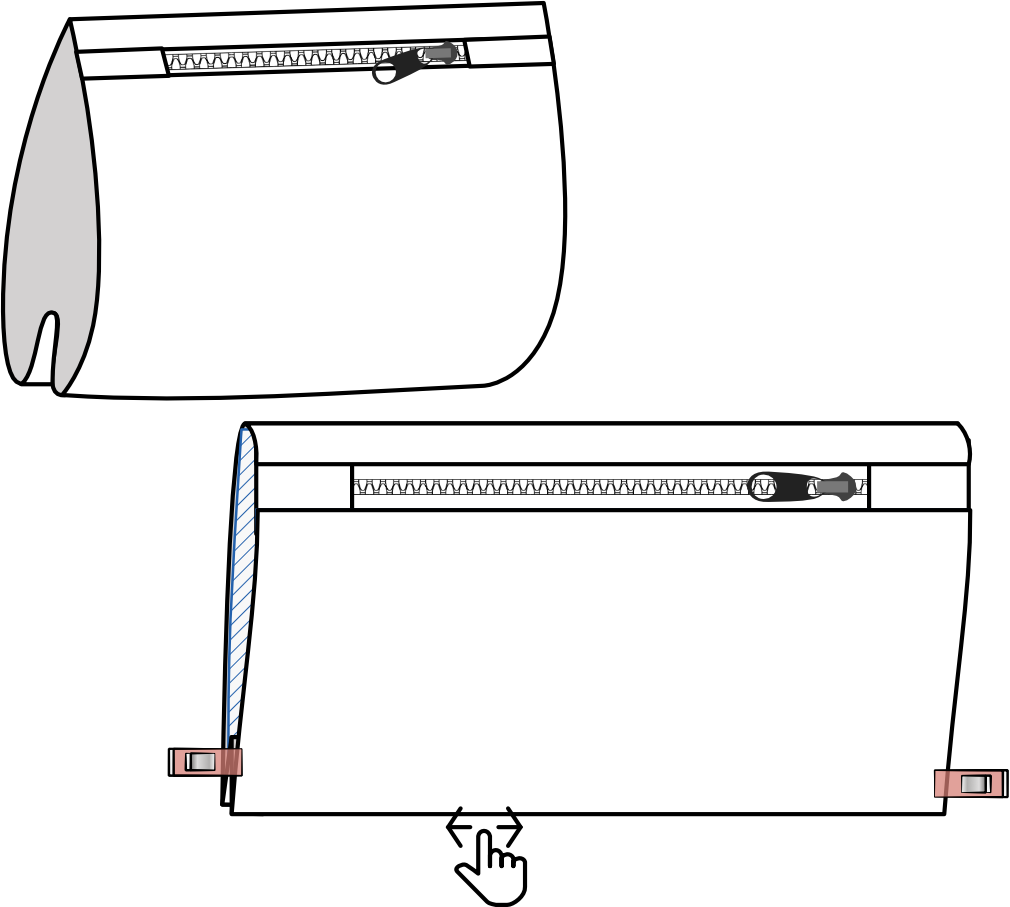

Step 6. Form the tube

Step 7. Form the bottom folds

Flat Pouch: Flatten the tube and crease a bottom edge.

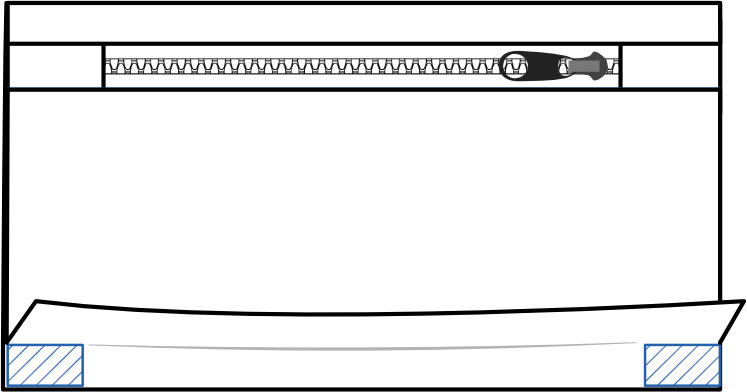

Standing Pouch: The bottom of the pouch uses a total of four notches, two on each side. Remove the paper so you can see the notches. Start on one side: align the two bottom notches and fold the fabric so that a section of the BODY is folded upward, forming a W shape.

Clip or pin to hold the folds in place. Repeat the same process on the other side. The W shape will give the pouch volume and help it stand up. Finger press the bottom flat to set the folds.

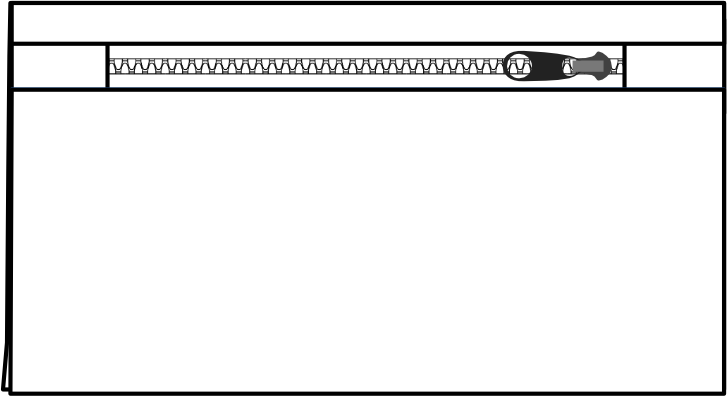

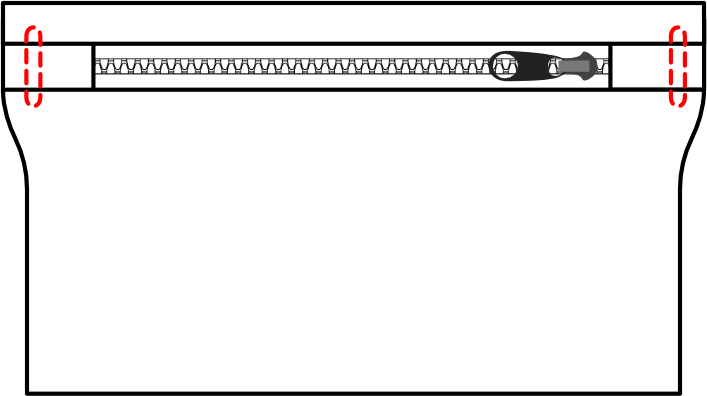

Step 8. Bond the side seams

Step 9. Reinforce the bottom corners

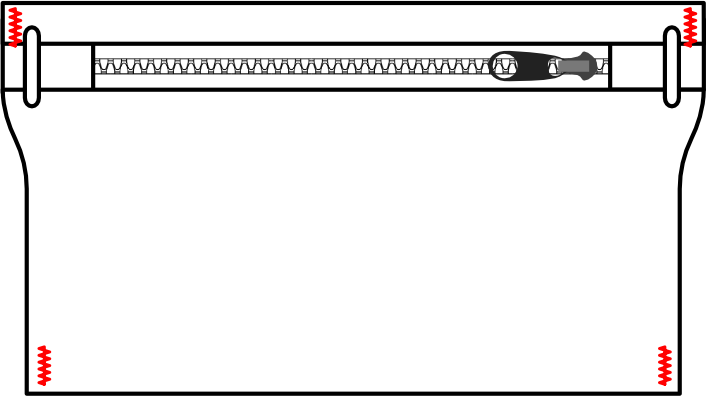

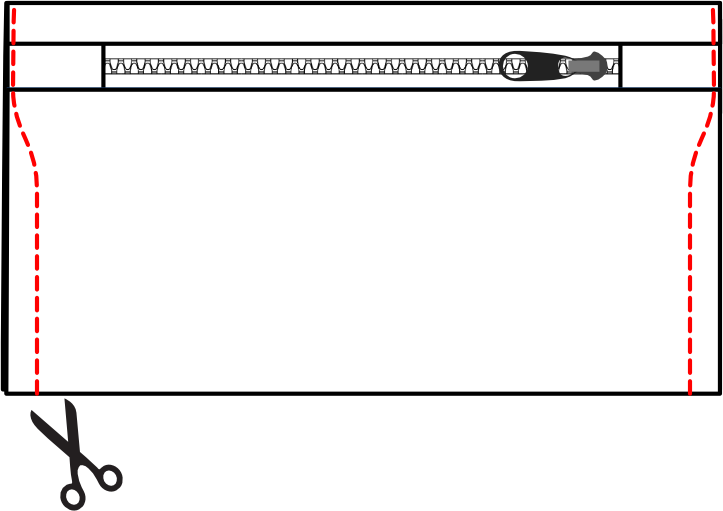

Step 10. Shape the side profile

To create a clean modern side view, draw a smooth profile at each side.

From the bottom, draw 1/2" (12 mm) in from the side and taper outward to the edge near the zipper. This creates a small tab at the zipper end for a lanyard or accessory loop.

Cut along the drawn profile. Repeat on the other side.