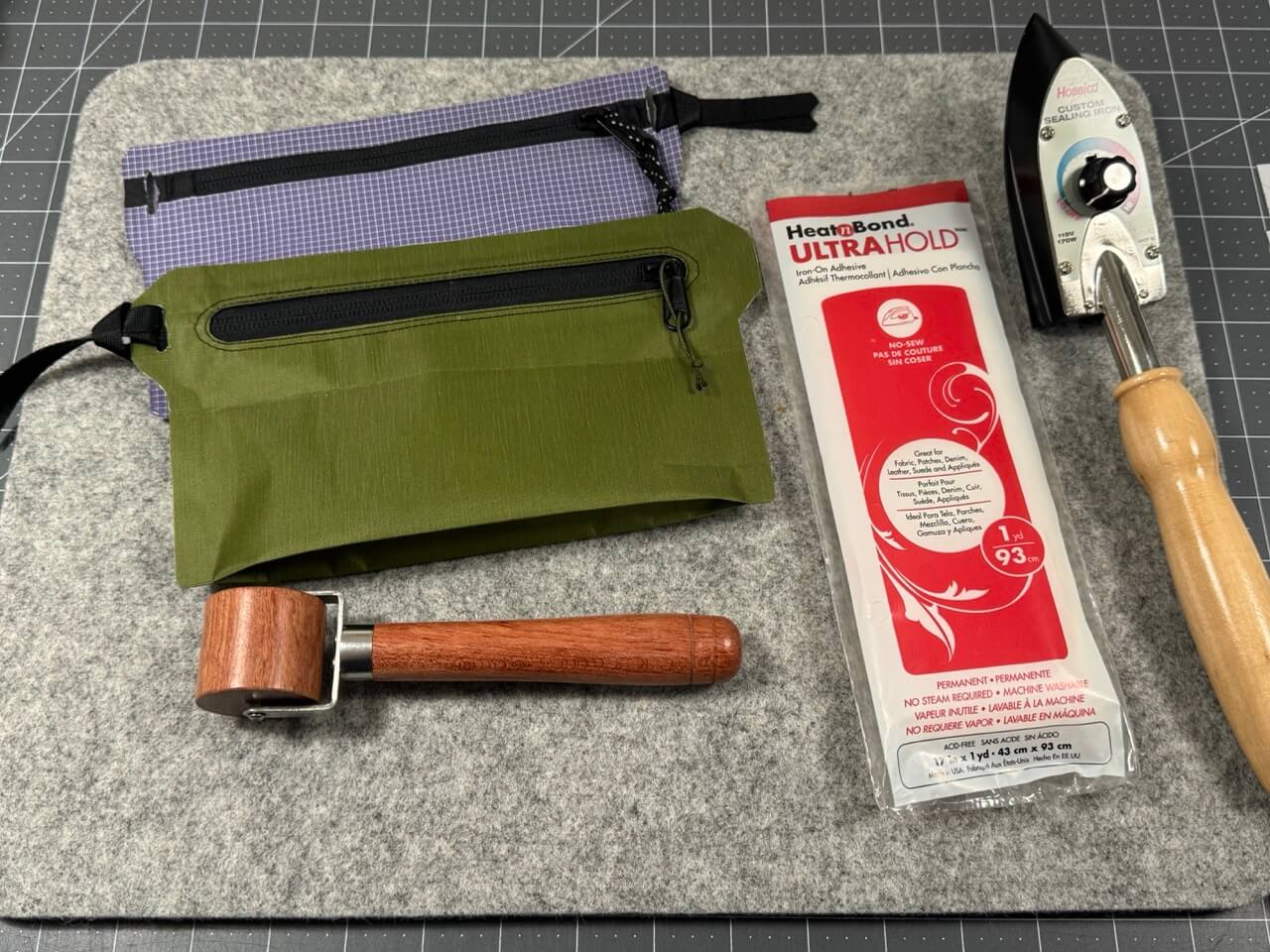

In commercial gear, welding refers to fusing thermoplastic materials together using heat and pressure instead of thread. At home, we can’t do that directly, but we can mimic the result by using a thin heat-activated adhesive film that melts under an iron and bonds two fabric layers together.

The seam isn’t truly welded, but it’s commonly called a bonded seam, and for small MYOG projects it gets surprisingly close in both function and appearance.

Bonded construction is widely used in performance apparel and outdoor gear to reduce bulk and eliminate stitching where it isn’t needed. One common industry reference is Bemis Sewfree, a family of heat-activated adhesive films designed for this exact purpose. The details aren’t important here. The takeaway is that this method is proven. We’re just adapting it for home tools and small projects.

For items like pouches and organizers, bonded seams can offer:

- Clean, low-profile edges

- No needle holes

- Improved water resistance

- A modern, technical look