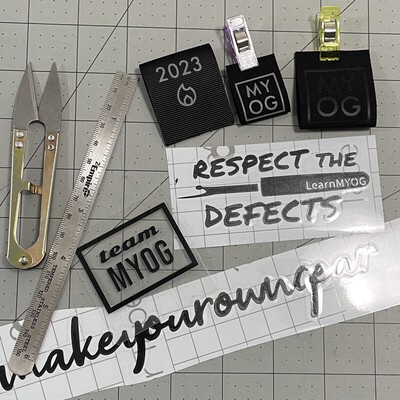

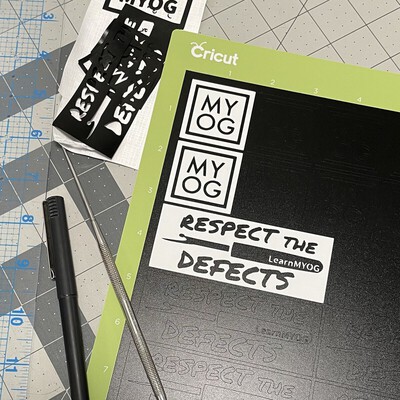

Digital Cutters for Gear Makers

Cricut, Sillhouette, USCutters, etc. Useful for technial gear and apparel workshop?

Some thoughts and considerations after using a Cricut Maker for a few years.

This is NOT a sponsored page. Below is my unbiased answers to frequently asked questions about the Cricut Maker and digital my workflow.