This page contains affiliate links, meaning I make a commission for qualified purchases, at no cost to you. See Disclosures for more information.

Fabric selection for the main body of backpacks and bikepacking bags often trades weight against

durability and cost.

Non-breathable coated fabrics and laminates provide water resistance against inclement weather,

but most are not 100% waterproof.

Fabrics woven with higher denier threads feel more durable and help provide a more rigid

structure.

Fabric images were shot top-down from the same height for a consistent scale.

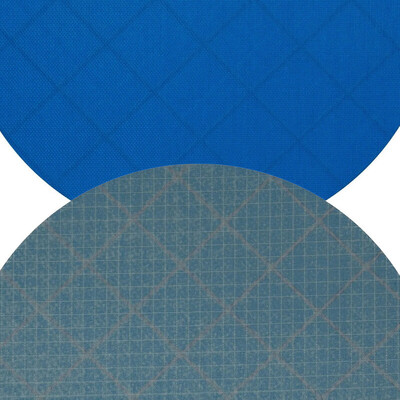

HyperD™ 300

300D PU Coated Polyester with DWR face.

Excellent beginner pack fabric due to low cost, high sewability, and waterproofing.

Finish has a shiny diamond ripstop pattern in popular colorways.

For additional waterproofing, seal internal seams with

Seam Grip® or heat activated PU Seam Tape.

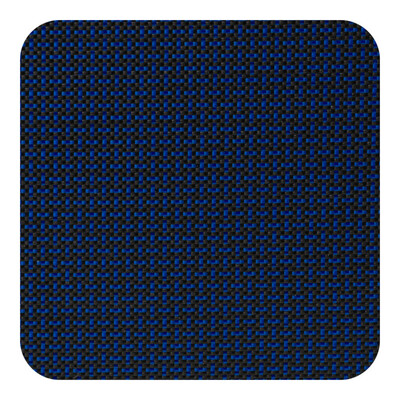

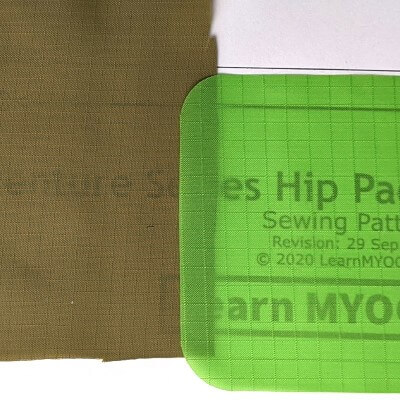

Robic® Ripstop

210D PU coated Nylon with DWR face.

Strong Nylon 6 content, Robic has excellent durability and water repellence.

Robic sews great, resists fraying, can be matched to 100D or 420D variants, and is

easy on the wallet.

For additional waterproofing, seal internal seams with Seam Grip® or heat activated PU Seam Tape.

210D Gridstop

A modern classic pack fabric, Gridstop has an HDPE or UHMWPE (Dyneema) reinforcing ripstop grid in high constrast white. 210D Gridstop is high strength, waterproof with DWR and PU coating, yet can be very difficult to cut often dulling scissors quickly.

X-Pac® VX21

X-Pac VX line is a four-layer laminate with a nylon face, waterproofing layer, x-ply, and 50D poly backer.

It's stiff giving packs rigid structure, but curls upon cutting, and needle punctures compromise water resistance.

There are multiple weights, colors, and variants offered. VX21 is the most popular. RX15 is a variant without the poly backer so it can be seam taped with PET Seam Tape.

ECOPAK™ EPX200

ECOPAK EPX is a 100% recycled laminate with PFC-free DWR.

It's rigid giving packs a bit of structure, has a square grid for efficient pattern layouts, and is the x-grid is smooth for better abrasion resistance. Needle punctures compromise water resistance.

There are multiple weights, colors, and variants offered. ECOPAK EPLX is a variant that can be seam taped with PET Seam Tape.

ECOPAK™ ULTRA

Cuben fiber is so 2018. Challenge Ultra is the new cottage darling. With a dyneema-like UHMWPE / polyester woven face and PET film backing for waterproofing, Ultra 200 and 400 are very strong for their weight, yet its long term durability and resistance to delamination is yet to be seen. Ultra is sparsely available and in few colors. Seam tape with PET Seam Tape.

Stuff Sacks and Linings

For lightweight bags, stuff sacks, pack liners, pockets, etc durability generally isn't a major

concern. Weight and water proofness may be. A color pop or bright interior are crucial.

Coated and impregnated fabrics are highly water resistent, but are not 100% waterproof.

Ripstop grids increase the tear resistance of these lightweight fabrics. Non-coated variants are

breathable and may be calendered to be downproof and windproof.

1.1oz Silnylon

While non-breathable, silnylon is strong and easy to wipe clean.

Numerous colors can be found and its very affordable.

Similarly silpoly is an impregnated polyester. Nylon is stronger, but silpoly is more UV resistant and has less stretch making it better for tarps.

1.9oz Coated Ripstop

Lightweight, widely available, and low cost.

PU coated on the underside with a DWR on the face, coated ripstop is water repellant

and non-breathable.

Thicker than 1.1 oz sil and less slippery so its easier to sew but its not as easy to wipe clean.

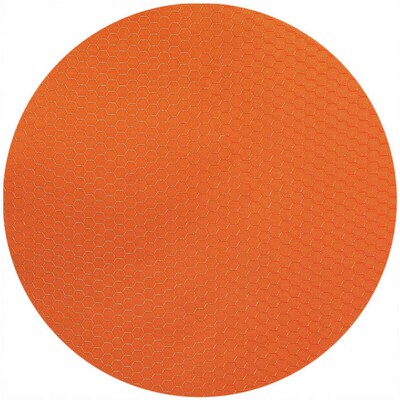

Hex70 XL - PU3000

Higher strength and more durable than 1.9oz PU coated nylon, 2.2 Hex70 XL comes in coated and uncoated variants.

PU coated is preferred for most gear. An excellent fabric for many uses, the wide color range, low cost, and extra width make it highly recommended.

Mesh and Stretch Pockets

Mesh pockets, stretch bottle pockets, padded back panels, and vest straps.

Fabrics are typically described to stretch in one direction (2-way) or lenght and width (4-way).

Varying percent stretch and durability are important to selecting the right materials.

Ordering samples is a smart idea as sources and descriptions vary significantly.

These stretch wovens are generally a blend of either polyester or nylon with elastane/spandex/lycra.

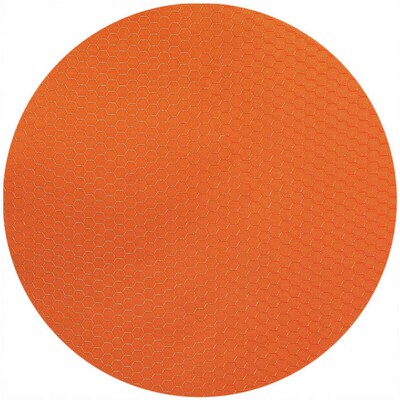

Lycra Mesh

Excellent for very stretchy pockets, Lycra mesh is a very lightweight, tightly woven 4-way stretch.

Its quite durable for the weight however not the best choice for high abrasion areas like a bottom pocket.

Expect 50-80% stretch depending on weight.

For higher abrasion, and weight, look to Spandura or medium weight lycra mesh similar to spandex for athletic wear.

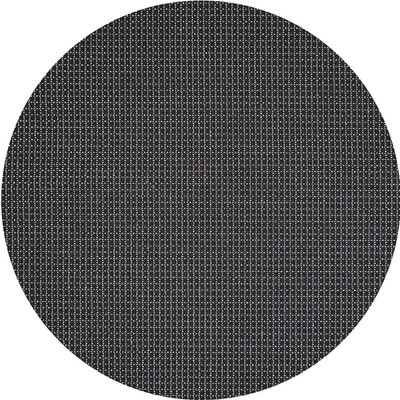

Duraweave

Unlike spandex, Duraweave is very strong and has less stretch.

These stretch meshes are durable, maintain stretch well, and many are quite abrasion

resistant. 2-way and 4-way will stretch to about 20-30% depending on lycra content.

Dyneema Stretch Mesh

High tenacity nylon blended with Dyneema adds significant strength and durability to this new wave of stretch mesh fabrics.

Excellent choice for bottom pockets or front pockets intended for rugged environments. Downside is less stretch overall than heavy lycra options.

3D Spacer Mesh

For padded back panels and shoulders straps, 3D Spacer Mesh is one of the few air mesh materials widely available to MYOGers.

Typically found in 3mm (1/8") or 6mm (1/4").

Breathable and padded, it can be used either side facing skin.

It sews well as its easy to compress and has very minimal stretch. I prefer 3mm and often line with a PU coated ripstop panel.

Foam and Frame Sheets

Shoulder straps, hip belts, suspension back panels, and rigid bikepacking bags are lined with foam.

For load carrying backpacks, a combination of foam and plastic frame sheet provide effective weight transfer to a hip belt.

Closed cell foam is desired as a denser more durable foam that won't absorb water. Its easy to cut with a hobby knife or rotary cutter and readily accessible to purchase online for cosplay community.

PE foam is used by the big brands and I'm still looking for a source for low MOQ, small sheets for hobbyists.

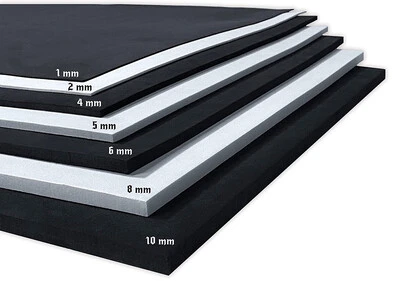

EVA Foam

For padding hip belts, shoulders straps, and padded bags, EVA foam is an excellent choice. As closed cell foam its available in many thicknesses and densities. The generic cosplay foam is perfect for pack making and easy to work with.

4-6mm thicknesses work well for back panels and 6-10mm is perfect for padding strap and hip belts.

If your project requires sewing through the foam, be sure to check the max height of your presser foot to ensure you choose the right size foam!

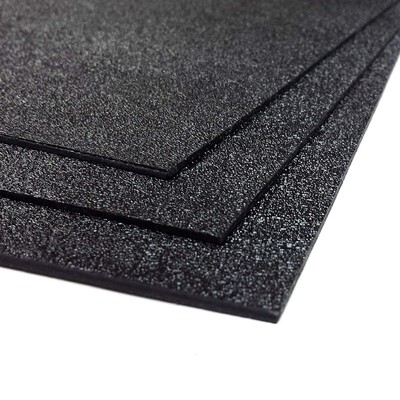

ABS Plastic

For load carrying backpacks, weight transfer to a hip belt requires some sort of back suspension. A plastic frame sheet with or without metal stays is a lightweight option. ABS plastic is almost always black with one side textured and one side smooth. Its easily cut with woodworking tools or by scoring and snapping a hobby knife. I find this 3-pack of 12x24 inch 1/16" thick sheets to be the most economical option.

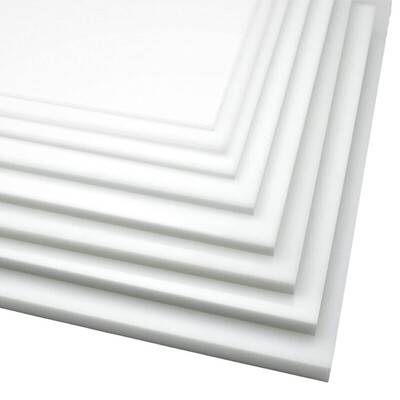

HDPE Plastic

HDPE plastic is another common option for plastic frame sheets. HDPE is nearly always white, slightly translucent and extremely smooth and slippery. Its easily cut with by scoring and snapping however melts faster when using woodworking tools. A great source for HDPE is cheap cutting boards from the discount stores. HDPE scraps can be recycled alongside milk cartons.

The following rating system is subjective and based on my experience and research.

- 💪 Strength aka durability. Abrasion resistance, tear strength, seam strength, waterproofness, etc.

- 💲 Cost per yard. Some vendors offer 1/2 yard increments for small projects. Most fabrics here are 60" wide.

- 🧵 Sewability. How easy is the fabric to work with e.g. fraying, cutting, stitching, seam sealing, etc.

- 🪶 Weight. Approximate weight in ounce per square yard, sourced from vendor research.

For outdoor gear and apparel, use case and expected environment drive the main design criteria.

Weight often must be traded against durability and cost so you should decide for yourself when fabric weight is more important.

Back to top